Baihai Introduces the Emergency Shutdown Valve (ESDV) – AI-Powered Precision for Critical Safety

What is an ESDV?

Emergency Shutdown Valves (ESDVs) are essential safety components designed to isolate facilities in emergency situations, preventing escalation and ensuring operational security.

At Baihai, we leverage our AI-powered matching system to provide high-quality ESD valves that meet precise industry requirements, ensuring optimal performance, competitive pricing, and efficient delivery.

How ESDVs Work:

An emergency shutdown valve is equipped with a spring return actuator, allowing it to close automatically when the actuator pressure signal is released. This rapid response mechanism plays a crucial role in protecting personnel, assets, and the environment.

Why Baihai’s ESD Valves?

✔ Precisely Matched: Our AI-driven platform connects you with the best manufacturers, guaranteeing the perfect fit for your project.

✔ Fast & Reliable: We streamline procurement, reducing lead times and ensuring quick delivery.

✔ High Quality & Compliance: Sourced from top-tier manufacturers in Japan, our valves meet stringent industry standards.

Applications in Oil & Gas:

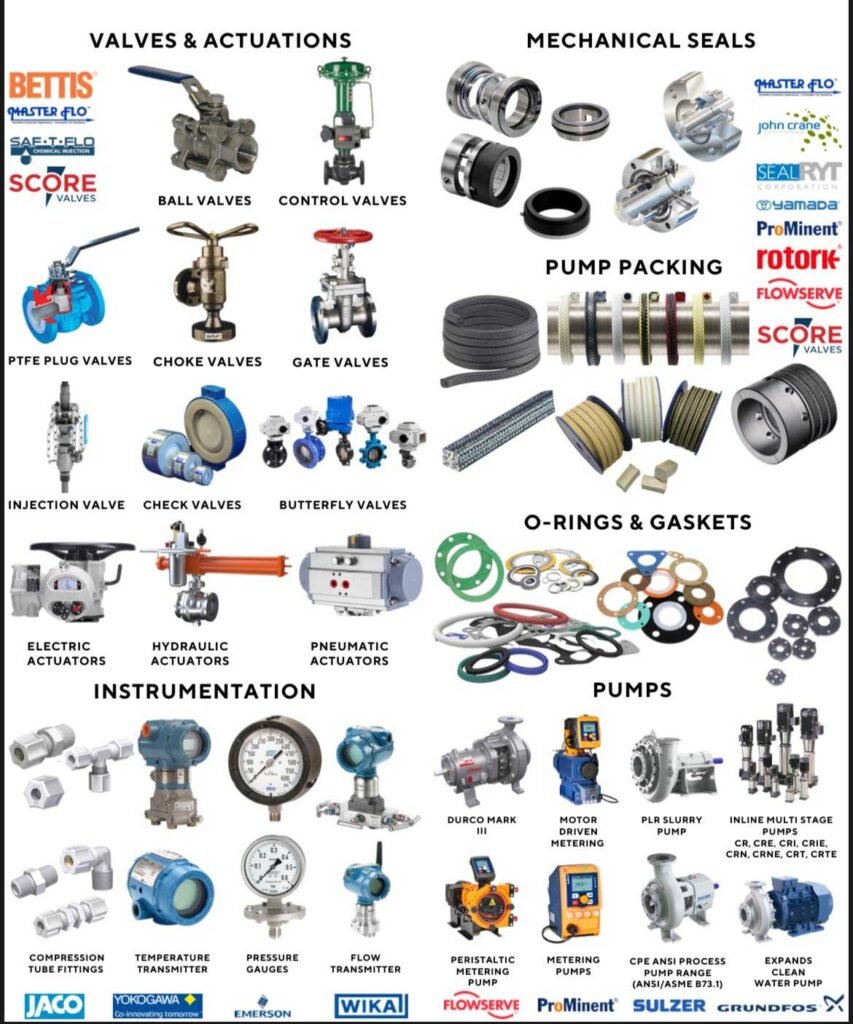

ESD valves are widely used to prevent hazardous escalation in oil and gas production, ensuring safe and efficient isolation. Typically, these are quarter-turn ball valves, but sliding stem gate valves and other types are also available based on project needs.

Baihai’s AI-driven procurement solutions ensure you receive the right ESD valve with the highest quality, at the best price, and delivered on time.

🔗 Learn more: https://baihai.jp/

Get in contact with us NOW to have the best quality of good and reliable parts for the choke and industrial valves in the industry! The only place where HIGH QUALITY and SPEED OF DELIVERY meets LOWER PRICES!